vickers hardness test to determing flow stress|vickers hardness chart : ODM Vickers hardness measurements provide an easy and inexpensive method of evaluating the new local yield stress in cold‐formed workpieces. The well‐known available . webOs oásis, no deserto, são formados devido à ação do vento que desloca grandes porções de areia e rebaixa o nível do solo em determinadas regiões fazendo com que este fique próximo ao lençol freático subterrâneo. O .

{plog:ftitle_list}

2 de set. de 2020 · Clique para ver todos os jogos e resultados de San Marino no European Under-19 Championship 2023

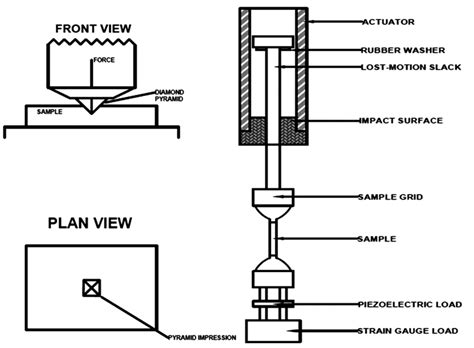

vickers hardness testing machine diagram

Static indentation tests: A ball, cone, or pyramid is forced into the sur-face of the metal being tested. The relationship of load to the area or depth of indentation is the measure of hardness, such as in Brinell, Knoop, Rockwell, and Vickers hardness tests. RT hardness tests were performed at different loads and length scales on specimens, in attempts to determine any change in the properties between surface and bulk .

volumetric karl fischer titration ppt commercial

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .Vickers Hardness Testing Formulas, Calculator and Review. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid . Vickers hardness measurements provide an easy and inexpensive method of evaluating the new local yield stress in cold‐formed workpieces. The well‐known available .

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low . The Vickers procedure can be used to test the hardness of metals and other equally hard materials. However, it was primarily designed to focus on softer materials like plastic specifically on their ability to resist deformation .

The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) . Then several other hardness tests have been developed, including the Vickers, Berkovich, Knoop and Rockwell tests [2], [3], [4]. The hardness value is usually defined as the . There are five commonly-used methods of hardness testing: (a) Brinell hardness test, (b) Rockwell hardness test, (c) Vickers test, (d) Knoop hardness test, and (e) .

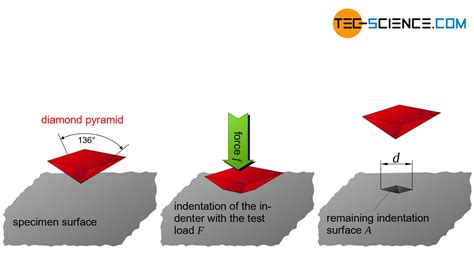

The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . The yield stress can be approximated from the hardness (given in HV) as . The microstructure, hardness, and chemical composition gradient were evaluated using optical metallography, Vickers hardness testing, nanoindentation, and SEM/EDX analysis. The paper presents a method for estimating the value of equibiaxial stress in a surface layer of a material by using a modified hardness measurement procedure with a Vickers indenter. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for measuring the Brinell hardness of metals. ISO 6507: This standard contains the details for the Vickers hardness test in metallic materials.

One such product property is the new yield strength, which can be approximated by the final flow stress of the workpiece material during forming. Vickers hardness measurements provide an easy and inexpensive method of evaluating the new local yield stress in cold-formed workpieces. The well-known available models given in literature to convert .A standard Vickers Hardness test was conducted on a metal specimen. Determine the Vicker’s hardness number and the tensile stress of the specimen. The applied load was 10 kgf, and the standard indentor left an indentation with diagonal d = 0.217 mm. Assume that the metal is hard.Vickers Hardness Test... 15 1.4. Relation between flow strength and hardness . Flow Stress K Strength Index . Hence numerous mechanical characterization tests are used to determine their conformance to desired specifications. Today, in almost all metal manufacturing .The Vickers method is a static hardness testing method, which can be further characterised as follows: . This means that the size of indentation left by the indenter is measured to determine the hardness value of a test specimen. Indenter shape and material: The indenter is an equilateral pyramid (with a square base) made of diamond with a .

Vickers versus Knoop hardness testing In most cases, the Vickers hardness test is used to determine hardness in materials in the micro hardness test load range. However, the Knoop hardness test is often used when hardness testing thin layers, such as coatings, or to overcome the problem of cracking in brittle materials. The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.Static indentation tests are one way to determine hardness. For static indentation, a cone, pyramid, or ball is forced into the surface of the material. The relationship between the load applied for a given length of time and the area or depth of the indentation indicates the hardness. In Vickers hardness testing, a square pyramidal diamond .

IJRRAS 17 (1) November 2013 Medeiros &Dias Analysis of Vickers Hardness Testing 10 elastic-plastic stress-strain response [3, 4]. Therefore, some authors are developing methodologies based on non-conventional tests and in order to determine mechanical properties of such materials. In a study conducted by Flury et al. , ISO 4049 was compared to the Vickers MH test to determine bulk-fill resin composite depth of cure. Results showed that ISO 4049 tended to overestimate depth of cure when compared to Vickers MH, which gave the depth at which at least 80% of maximum hardness was obtained.One of the more convincing aspects that determines a material's fitness for a particular function is its hardness. As a result, a hardness test is necessary to establish the degree to which a material can support the str uctural integrity of an object. One of these tests is the Vickers technique and it has been demonstrated to be a very good way of evaluating a material's . Keywords carbon/alloy steels, hardness, mechanical testing 1. Introduction Hardness is widely used as an indicator of the mechanical properties of a metal, because it can be quickly and easily measured and the test itself is essentially nondestructive. In simple terms, hardness can be defined as the resistance of a metal to deformation.

For non- strain-hardening materials the Vickers hardness number HV defined as (1 1 Indenter Force (in kg) Surface Area of the Imprint (in mm’) is related to the constant yield stress Y by [I]: HV = HV= 2.9 Y to 3.0 Y (2) For strain-hardening materials, Tabor [2] suggests on empirical bases to use a similar expression as in the case of . Based on the power-law stress–strain relation and equivalent energy principle, theoretical equations for converting between Brinell hardness (HB), Rockwell hardness (HR), and Vickers hardness (HV) were .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion . [17] used a 3D numerical simulation of micro-indentation test using a Vickers indenter was performed to determine the geometrical parameters of imprint after elastic recovery and to estimate the .

Hardness test is a reasonable substitute for tensile strength in determining the tempers of Al alloys. 46, 47 All heat-treated specimens were placed in a box filled with dry ice (−78 • C) that .For example, hardness from indentation tests on steel and copper alloys can be used as a rough guide to estimate tensile strength. Hardness tests, in most cases, are rapid and repeatable, and in many instances nondestructive. Therefore, hardness test represents an important means of quality control. All the widely used hardness measurements .

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements. To determine the Brinell hardness of a metal material, apply a certain load F with a spherical indenter of diameter D onto its surface and maintain it for a specific duration. . Note: 1. The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. . Hardness test characteristics. ① The .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method , which is mostly used for small parts, thin sections, or case depth work. As can be deducted from equation 3 of Tabor and 4 of Tekkaya, the relation between the stress and the Vickers hardness as well as the strain compensation for the strain induced during the hardness .The standard contains the suggested Vickers hardness range (ISO 6507). The Vickers hardness value ranges from 1 to 3.000 HV, depending on the test force and specimen material employed. The Vickers hardness range for NextGen’s Universal Hardness Tester for Vickers / Knoop, Rockwell and Brinell is 8-2900HV.Vickers Hardness Testing Formulas, Calculator and Review . The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number ( HV ) or Diamond Pyramid Hardness ( DPH ). The hardness number can be converted into units of pascals , but .

vickers hardness test theory

vickers hardness test pdf

volumetric titration karl fischer commercial

vickers hardness test explained

web21 de ago. de 2023 · The Lounging Lioness. If you can steal a private moment on the deck chair, the Lounging Lioness is a super-hot position to try. The receiving partner lies on top with their legs closed, providing .

vickers hardness test to determing flow stress|vickers hardness chart